technology

Excellence

Team

About

Afterone OÜ, established in 2004, is an Estonian metal subcontracting company specialized in CNC-turning and milling works. Afterone® is a family company whos mission is to become most advanced CNC-milling and -turning services provider in Estonia. The Company strives towards manufacturing excellence by continues improvement and its learning practices. Besides machining services Afterone developes state of art products to increase its customers production efficiency.

Afterone team is dedicated to contribute to the steady growth of company's competence. Constant strive to the better production practices and technology have made Afterone fastly growing and successful company. We believe that productivity is never taken for granted. It’s a result of a commitment to excellence, intelligent planning and focused effort.

Services

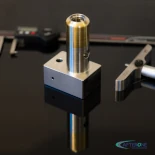

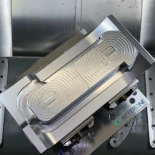

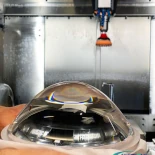

CNC turning and milling

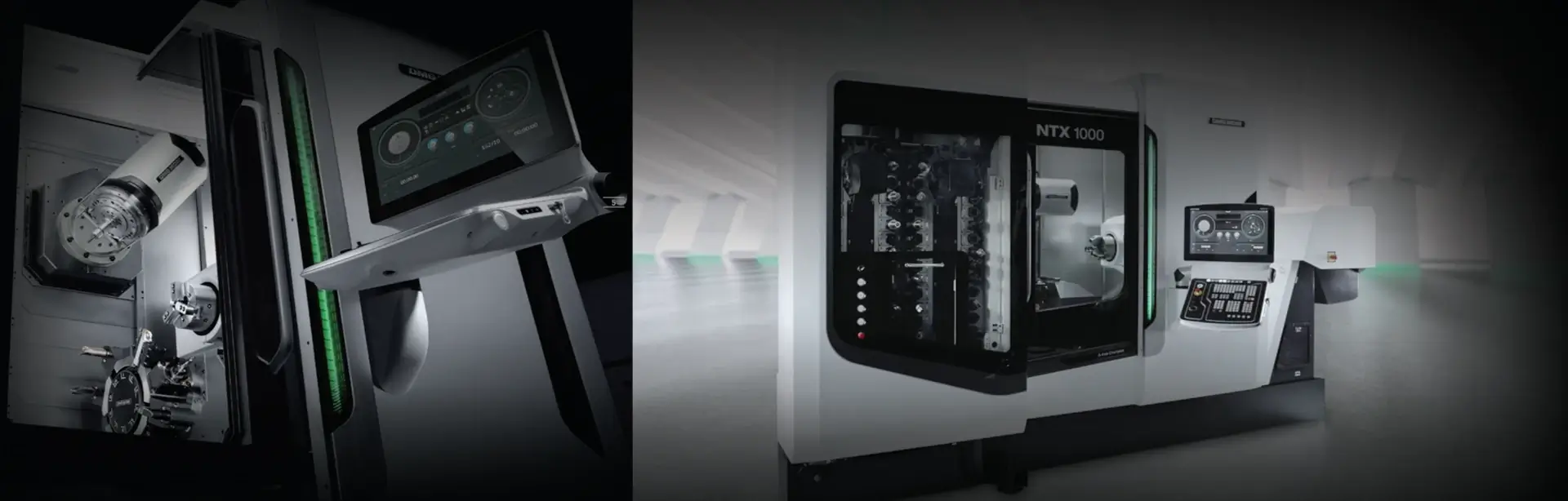

Afterone® offers CNC-turning and milling services. We machine all types of steel as well as engineering plastics. Having developed our in-house production planning system, every aspect of our customers needs is controlled in the best possible manner. Our production works in three shifts per day. Every minute of our production process is planned, controlled, and utilized. That makes us reliable and cost-effective suppliers for our customers.

We have chosen work only with the best machine tools available in the market and cooperate with word known brands like Okuma, DMG and Mitutoyo. We constantly improve our level of digitalization, CAD/CAM solutions and tools used in production. This strategy allows us to offer most advanced and stable service to our customers.

Complete Manufacturing Service

Our sister company EQUA OÜ is specialized on conventional metal works and provides good support and synergy. Joint expertise and both technologies in hand we are able to offer complete manufacturing solutions including:

- Metal constructions fabrication and assembly

- TIG, MIG and Aluminium welding

- Sheet metal and tube cutting and bending

- Plywood cutting and upholstering works

- Prototyping and white label products

Machine list

CNC Millturn machines

CNC-turning

CNC-milling

Quality and environment

At Afterone®, the concept of quality is much broader than the technical specifications of the products. The focus of quality management is on the customer and his expectations. Keeping promises, smooth customer communication and sustainable production are as important as the product in the picture.

ISO 9001 quality management system ensures smooth processing of orders from the time of the order until it is shipped to the customer. Focused process control enables us to avoid errors in the final control. We attach importance in minimizing our environmental impact according to ISO 14001 guidelines.

We always follow our principles:

- keep our promises

- value our employees and their self-development

- keep up with newest production technology

- resolve non-compliances with top priority

- offer partners just-in-time delivery agreements and stable prices

- value continuous learning and improvement at every company level

- comply with the legal requirements applicable to our activities

- we are commited to protecting the environment and preventing pollution

- we optimize material use

- we save electricity and water

- we handle chemicals and waste properly

Team Spirit Creates Excellence

We always strive towards exellence in every aspect of our work. We analyse our performance and critically evaluate our decisions. We have implemented best practises from lean manufacturing methods such as 5S, Andon, Kaizen and Kanban. This enables us to achieve maximum efficiency and smooth production flow.